The Benefits of ERP Software for Filters Manufacturing

The Benefits of ERP Software for Filters Manufacturing

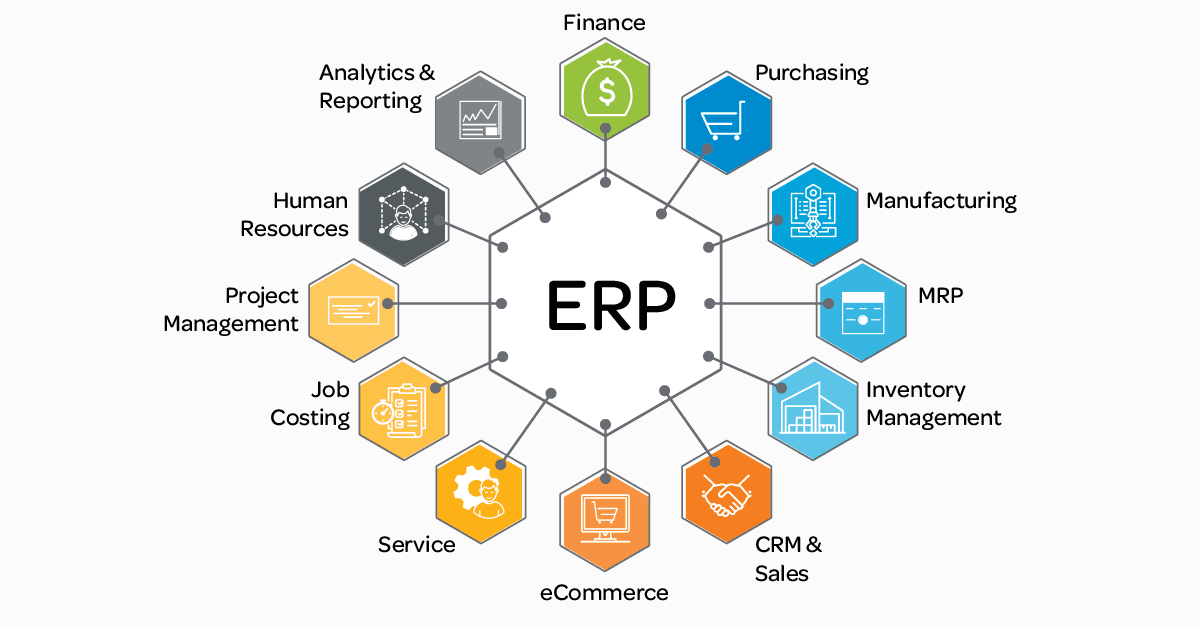

Hey there! Are you in the filters manufacturing industry and looking to streamline your operations for better efficiency and productivity? Well, consider implementing ERP software into your business process. ERP software can offer a wide range of benefits for filters manufacturing companies, from inventory management to production planning. With the help of ERP software, you can easily track and manage all aspects of your manufacturing process in one centralized system, ultimately saving time and reducing operational costs. Read on to discover the many advantages of utilizing ERP software in the filters manufacturing industry.

Importance of ERP Software in Filters Manufacturing

ERP software plays a crucial role in the filters manufacturing industry by streamlining processes, increasing efficiency, and improving overall productivity. This powerful tool helps filters manufacturing companies manage their operations smoothly, from inventory management to production planning and customer relationship management.

One of the key benefits of using ERP software in filters manufacturing is its ability to integrate all aspects of the business into one central system. This integration allows for real-time communication between departments, ensuring that everyone is on the same page and working towards common goals. With ERP software, manufacturers can easily track inventory levels, monitor production schedules, and analyze sales data to make informed decisions.

Furthermore, ERP software helps filters manufacturing companies optimize their production processes by providing insights into production costs, lead times, and resource utilization. By having access to this data, manufacturers can identify areas for improvement and implement strategies to enhance efficiency and reduce waste. This results in lower production costs, faster turnaround times, and higher quality products.

In addition, ERP software enables filters manufacturing companies to better manage their supply chain relationships. By tracking supplier performance, monitoring inventory levels, and automating reorder processes, manufacturers can ensure that they have the right materials on hand when needed. This not only reduces the risk of stockouts but also helps companies build stronger relationships with their suppliers.

Another important feature of ERP software in filters manufacturing is its ability to streamline the order-to-cash process. By automating order processing, invoicing, and payment collection, manufacturers can reduce manual errors, improve cash flow, and enhance customer satisfaction. This seamless process ensures that orders are fulfilled promptly and accurately, leading to happier customers and repeat business.

Overall, ERP software is a valuable tool for filters manufacturing companies looking to stay competitive in today’s fast-paced market. By providing a centralized system for managing all aspects of the business, optimizing production processes, and improving supply chain relationships, ERP software helps manufacturers achieve higher levels of efficiency and profitability. In conclusion, investing in ERP software is essential for filters manufacturing companies that want to thrive and grow in an increasingly competitive industry.

Key Features to Look for in ERP Solutions for Filters Manufacturing

When choosing an ERP solution for filters manufacturing, there are several key features that you should look for to ensure that the software meets the specific needs of your industry. Here are some important features to consider:

1. Industry-Specific Functionality: One of the most important factors to consider when selecting an ERP solution for filters manufacturing is industry-specific functionality. The software should have features that are tailored to the needs of the filters manufacturing industry, such as inventory management for different types of filters, production planning for varying filter sizes, and quality control tools to ensure that the final products meet industry standards.

2. Customization Options: In filters manufacturing, no two companies are exactly alike, so it is important to choose an ERP solution that offers customization options. Look for software that allows you to tailor the system to meet your specific needs, whether that means adding custom fields to track unique data points, creating custom reports to analyze production efficiency, or integrating with other software systems to streamline processes.

3. Inventory Management: Efficient inventory management is crucial for filters manufacturing companies, as they need to maintain accurate stock levels of various filter components to meet customer demand. Look for an ERP solution that offers real-time inventory tracking, automated reorder points to prevent stockouts, and the ability to track the movement of filters throughout the production process.

4. Production Planning and Scheduling: Filters manufacturing companies often have complex production processes that involve multiple stages and require coordination between different departments. Choose an ERP solution that offers robust production planning and scheduling tools, such as capacity planning to optimize resources, production forecasting to anticipate demand, and scheduling algorithms to minimize downtime and maximize efficiency.

5. Quality Control and Compliance: Quality control is essential in filters manufacturing to ensure that the final products meet industry standards and customer expectations. Look for an ERP solution that offers quality control tools, such as inspection checklists, non-conformance tracking, and production traceability, to monitor product quality at every stage of the production process and ensure compliance with industry regulations.

6. Integration Capabilities: To maximize the benefits of an ERP solution for filters manufacturing, it is important to choose software that can seamlessly integrate with other systems that your company uses, such as CRM software for managing customer relationships, accounting software for financial reporting, and e-commerce platforms for online sales. Look for an ERP solution that offers built-in integrations or the ability to create custom integrations through APIs to streamline data sharing and improve overall efficiency.

By considering these key features when selecting an ERP solution for filters manufacturing, you can ensure that the software meets the specific needs of your industry and helps your company improve efficiency, productivity, and profitability.

Benefits of Implementing ERP Software in Filters Manufacturing Process

Implementing ERP software in the filters manufacturing process can bring numerous benefits to the business. Most notably, it can streamline operations, improve efficiency, and increase overall productivity. By integrating all aspects of the manufacturing process into a single system, ERP software can help in managing inventory, tracking orders, scheduling production, and monitoring quality control. This can result in reduced lead times, minimized waste, and improved customer satisfaction.

One of the key benefits of ERP software in filters manufacturing is increased visibility and transparency. With all data stored in a centralized system, managers and employees can easily access real-time information about production processes, inventory levels, and customer orders. This enables better decision-making and planning, as well as the ability to quickly identify and address any issues that may arise during the manufacturing process.

Additionally, ERP software can help in automating repetitive tasks, such as data entry, scheduling, and reporting. This not only saves time and reduces errors, but also frees up employees to focus on more strategic tasks that can drive innovation and growth. By streamlining processes and eliminating manual tasks, ERP software can improve overall operational efficiency and effectiveness.

Furthermore, ERP software can provide valuable insights and analytics that can help in optimizing the manufacturing process. By analyzing data on key performance indicators, such as production costs, inventory turnover, and lead times, manufacturers can identify areas for improvement and implement strategies to boost profitability and competitiveness. With advanced reporting and analytics capabilities, ERP software can help in monitoring performance, identifying trends, and making informed decisions to drive business growth.

In conclusion, implementing ERP software in the filters manufacturing process can offer numerous benefits, including streamlined operations, improved efficiency, increased productivity, enhanced visibility, and better decision-making. By integrating all aspects of the manufacturing process into a single system, ERP software can help in managing inventory, tracking orders, scheduling production, and monitoring quality control. With automation, analytics, and reporting capabilities, ERP software can drive innovation, improve competitiveness, and support business growth in the filters manufacturing industry.

Challenges and Considerations when Implementing ERP for Filters Manufacturing

Implementing ERP software for filters manufacturing can be a complex process due to the specific requirements of this industry. There are several challenges and considerations that need to be taken into account in order to ensure a successful implementation:

1. Customization for the Filters Manufacturing Industry: One of the main challenges when implementing ERP software for filters manufacturing is the need for customization to meet the specific needs of this industry. Filters manufacturing involves complex processes and requirements that are different from other manufacturing sectors. Therefore, the ERP software needs to be able to support these unique processes, such as batch production, quality control, and inventory management specific to filters.

2. Integration with Existing Systems: Another consideration when implementing ERP for filters manufacturing is the integration with existing systems. Many filters manufacturing companies already have legacy systems in place for managing their operations. It is important that the new ERP software can seamlessly integrate with these systems to avoid disruptions in production and to ensure a smooth transition.

3. Training and Change Management: Implementing ERP software in any industry requires adequate training for employees and effective change management strategies. This is especially crucial in filters manufacturing, where employees may be used to working with manual processes or outdated systems. Proper training and change management are essential to ensure that employees are able to adapt to the new ERP system and maximize its benefits.

4. Data Migration and Clean-Up: One of the most critical considerations when implementing ERP for filters manufacturing is the process of data migration and clean-up. Filters manufacturing companies typically have large amounts of data stored in various systems, including production schedules, inventory levels, supplier information, and customer orders. Migrating this data to the new ERP system can be a complex and time-consuming process, requiring careful planning and execution.

During the data migration process, it is essential to clean up the data to ensure its accuracy and consistency in the new system. This involves identifying and resolving any duplicate, outdated, or incorrect data to prevent errors and inefficiencies in the ERP software. Data clean-up is a crucial step in ensuring the success of the ERP implementation and the smooth operation of the new system.

In conclusion, implementing ERP software for filters manufacturing presents unique challenges and considerations that need to be carefully addressed. By customizing the ERP system for the filters manufacturing industry, integrating it with existing systems, providing adequate training and change management, and properly handling data migration and clean-up, filters manufacturing companies can successfully implement ERP software to streamline their operations and improve efficiency.

Case Studies: Successful Implementation of ERP Software in Filters Manufacturing Industry

ERP software has become essential for filters manufacturing companies to streamline their operations, increase productivity, and improve overall efficiency. In this article, we will explore several case studies of successful ERP software implementation in the filters manufacturing industry.

Case Study 1: XYZ Filters

XYZ Filters, a leading manufacturer of industrial filters, was facing challenges with managing their production processes and inventory efficiently. They decided to implement an ERP software solution tailored to their specific needs. The ERP software helped XYZ Filters to automate their inventory management, streamline production scheduling, and improve communication between different departments. As a result, they saw a significant increase in productivity and a reduction in lead times.

Case Study 2: ABC Filtration

ABC Filtration, a medium-sized filters manufacturing company, was struggling with tracking orders, managing inventory, and keeping up with customer demands. After implementing an ERP software system, they were able to integrate all their business processes into a single, centralized platform. This enabled ABC Filtration to monitor their production in real-time, optimize their inventory levels, and provide better customer service. The ERP software also helped them to forecast demand accurately and plan production more efficiently.

Case Study 3: DEF Filters

DEF Filters, a family-owned filters manufacturing business, was experiencing difficulties with managing their growing operations and maintaining quality standards. By implementing an ERP software solution, DEF Filters was able to standardize their production processes, enforce quality control measures, and improve traceability of their products. The ERP system also enabled DEF Filters to streamline their procurement process, reduce waste, and optimize their production costs.

Case Study 4: GHI Technologies

GHI Technologies, a global filters manufacturing company, needed a comprehensive ERP software solution to support their diverse product range and international operations. They chose an ERP software provider that offered multi-language and multi-currency support, along with features for managing complex supply chains and regulatory requirements. The ERP software helped GHI Technologies to consolidate their global operations, improve collaboration between different facilities, and comply with industry regulations in various regions.

Case Study 5: JKL Solutions

JKL Solutions, a small filters manufacturing startup, was looking for an ERP software solution that could grow with their business. They selected a cloud-based ERP system that could be easily scaled up as their production volumes increased. The ERP software enabled JKL Solutions to manage their inventory, production schedules, and financials effectively without investing in expensive hardware or IT infrastructure. With real-time access to business data and analytics, JKL Solutions was able to make informed decisions, forecast demand accurately, and expand their market reach.