Understanding the ERP Manufacturing Process

Understanding the ERP Manufacturing Process

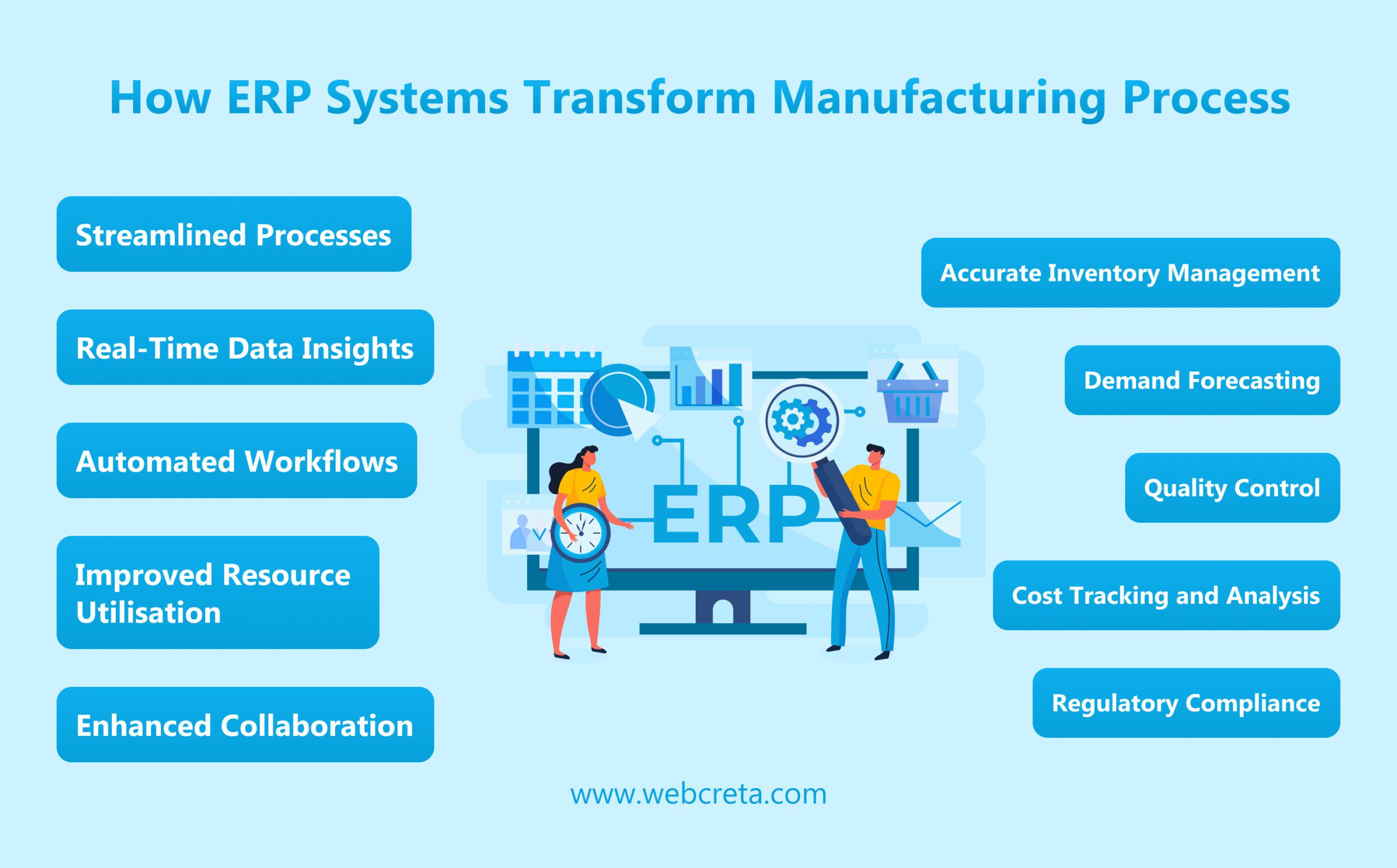

Welcome to the world of ERP manufacturing process! Have you ever wondered how companies efficiently manage their production, inventory, and supply chain? In this article, we will explore the ins and outs of ERP (Enterprise Resource Planning) in the manufacturing industry. From streamlining operations to improving overall productivity, understanding the ERP manufacturing process is essential for anyone working in this sector. So, grab a cup of coffee and let’s dive into the fascinating world of ERP!

Introduction to ERP in Manufacturing

Enterprise Resource Planning (ERP) is a software solution that integrates various business processes and functions, such as accounting, inventory management, production planning, and customer relationship management, into a single system. In the manufacturing industry, ERP plays a crucial role in streamlining operations, enhancing productivity, and improving overall efficiency. From small-scale manufacturers to large multinational corporations, ERP solutions have become an essential tool for achieving success in a competitive market.

One of the key benefits of ERP in manufacturing is its ability to provide real-time visibility into all aspects of the production process. By centralizing data and automating tasks, ERP systems enable manufacturers to make informed decisions based on accurate and up-to-date information. This not only helps in reducing lead times and optimizing resource utilization but also improves the overall quality of products.

Another advantage of ERP in manufacturing is its ability to standardize processes and establish best practices across the organization. By implementing a common set of procedures and protocols, manufacturers can ensure consistency in operations and create a framework for continuous improvement. This not only leads to cost savings but also enhances collaboration and communication within the organization.

ERP solutions also play a critical role in enhancing supply chain management in the manufacturing industry. By integrating supply chain processes with production planning and inventory management, manufacturers can achieve greater transparency and control over their operations. This enables them to respond quickly to changing market demands, reduce inventory costs, and improve overall customer satisfaction.

Moreover, ERP systems help manufacturers in complying with industry regulations and standards. By providing tools for tracking and monitoring compliance requirements, manufacturers can ensure that their operations meet all legal and quality standards. This not only helps in avoiding costly penalties but also enhances the reputation and credibility of the organization in the marketplace.

In conclusion, ERP has revolutionized the manufacturing industry by providing a comprehensive solution for managing all aspects of the production process. From enhancing operational efficiency to improving supply chain management and ensuring regulatory compliance, ERP systems offer a wide range of benefits to manufacturers of all sizes. As technology continues to evolve, the role of ERP in manufacturing is only expected to grow, making it an indispensable tool for success in today’s competitive business environment.

Benefits of Implementing ERP in Manufacturing

Implementing an Enterprise Resource Planning (ERP) system in manufacturing can bring a multitude of benefits to a company. One of the main advantages is improved efficiency in the production process. ERP software streamlines various aspects of manufacturing, such as inventory management, production scheduling, and procurement, leading to reduced lead times and operational costs. By integrating different departments and functions within the organization, ERP helps to eliminate redundancies and improve communication, ultimately resulting in a more efficient manufacturing process.

Furthermore, implementing ERP in manufacturing allows for better decision-making and planning. The software provides real-time data and analytics that can be used to optimize production processes, forecast demand, and identify areas for improvement. With access to accurate and up-to-date information, manufacturing companies can make informed decisions that lead to increased productivity and profitability. ERP also enables companies to track key performance indicators (KPIs) and monitor their performance against industry benchmarks, helping them stay competitive in the market.

Another benefit of implementing ERP in manufacturing is improved inventory management. By centralizing data and automating inventory processes, companies can minimize stockouts, reduce excess inventory, and optimize their supply chain. This leads to lower carrying costs, improved order fulfillment rates, and better customer satisfaction. With ERP, manufacturers can track inventory levels in real-time, monitor product movement, and implement just-in-time inventory practices, ultimately reducing waste and improving overall efficiency.

Additionally, ERP systems provide greater visibility and control over the entire manufacturing process. By integrating different business functions – such as finance, sales, production, and logistics – companies can gain a holistic view of their operations and identify interdependencies that may impact productivity. This visibility allows manufacturers to identify bottlenecks, address issues in real-time, and make strategic decisions to improve overall performance. With ERP, companies can achieve greater operational transparency, traceability, and compliance with industry regulations.

Overall, implementing an ERP system in manufacturing brings numerous benefits, including increased efficiency, better decision-making, improved inventory management, and greater visibility and control over the production process. By leveraging the power of ERP software, manufacturing companies can streamline their operations, reduce costs, and enhance their competitive advantage in the market.

Key Features of ERP for Manufacturing Process

ERP (Enterprise Resource Planning) is a software system that integrates various processes and functions within an organization, providing a centralized platform for managing resources, data, and operations. In the manufacturing industry, ERP plays a crucial role in streamlining and optimizing production processes to improve efficiency and productivity. Here are some key features of ERP for the manufacturing process:

1. Inventory Management: ERP systems enable manufacturers to track and manage inventory levels in real-time. This helps in preventing stockouts, reducing inventory carrying costs, and ensuring smooth production flow. With ERP, manufacturers can set up automatic reorder points, monitor stock movements, and generate reports to optimize inventory levels.

2. Production Planning and Scheduling: ERP software helps manufacturers in planning and scheduling production activities based on demand forecasting, resource availability, and lead times. By integrating production planning tools with other modules such as inventory management and procurement, manufacturers can ensure efficient utilization of resources, optimize production schedules, and meet customer demand on time.

3. Quality Control and Compliance: One of the critical features of ERP for the manufacturing process is the ability to implement quality control measures and ensure compliance with industry regulations and standards. ERP systems offer tools for monitoring product quality throughout the production process, conducting inspections, and documenting compliance with quality standards. By automating quality control processes, manufacturers can improve product consistency, reduce defects, and enhance overall product quality.

4. Supply Chain Management: ERP systems provide manufacturers with visibility into their supply chain, enabling them to track suppliers, manage procurement, and optimize supply chain operations. By integrating supply chain management modules with other functions such as inventory control and production planning, manufacturers can streamline supply chain activities, reduce lead times, and enhance collaboration with suppliers for better procurement processes.

5. Real-time Reporting and Analytics: ERP systems offer manufacturers access to real-time data and analytics that help in monitoring key performance indicators, identifying trends, and making informed decisions. By generating customizable reports and dashboards, manufacturers can track production metrics, analyze performance, and identify areas for improvement. With ERP analytics, manufacturers can optimize processes, reduce costs, and drive operational efficiency.

6. Integration with IoT and Industry 4.0 Technologies: ERP systems are increasingly incorporating IoT (Internet of Things) and Industry 4.0 technologies to enable manufacturers to connect machines, sensors, and devices for data collection and analysis. By integrating IoT data with ERP systems, manufacturers can gain insights into equipment performance, predictive maintenance, and process optimization, leading to enhanced automation, efficiency, and productivity.

Overall, ERP systems offer a comprehensive solution for manufacturers to streamline and optimize their production processes, improve quality control, and enhance collaboration across the supply chain. By leveraging the key features of ERP for the manufacturing process, manufacturers can achieve operational excellence, competitive advantage, and sustainable growth in the dynamic manufacturing industry.

Challenges in Implementing ERP in Manufacturing

Implementing an ERP system in the manufacturing industry can be a complex and daunting task. There are several challenges that organizations may face during the implementation process.

One of the main challenges is the resistance to change from employees. Many employees may be comfortable with the existing processes and systems and may be resistant to adopting a new ERP system. This resistance can lead to delays in implementation and decreased productivity as employees struggle to adapt to the new system.

Another challenge is the high cost of implementing an ERP system. The initial investment required to implement an ERP system can be substantial, and many organizations may struggle to justify the cost. Additionally, there are ongoing costs associated with maintenance, training, and upgrades, which can add to the financial burden.

Lack of expertise and resources is another common challenge in implementing ERP in manufacturing. Many organizations may not have the necessary skills or resources in-house to successfully implement an ERP system. This can lead to delays, errors, and inefficiencies in the implementation process.

Furthermore, data migration and integration can be a significant challenge when implementing an ERP system in manufacturing. Organizations may have large volumes of data stored in multiple systems that need to be migrated to the new ERP system. This process can be time-consuming and complex, requiring careful planning and execution to ensure that all data is transferred accurately.

In addition to these challenges, customization and integration with existing systems can also prove to be difficult when implementing an ERP system in manufacturing. Every organization is unique, with its own processes and systems in place. Customizing the ERP system to meet the specific needs of the organization and integrating it with existing systems can be a complex and time-consuming process.

In conclusion, implementing an ERP system in the manufacturing industry is not without its challenges. From resistance to change and high costs to lack of expertise and data migration issues, organizations must be prepared to address these challenges head-on in order to successfully implement an ERP system and realize the benefits it can bring to their manufacturing processes.

Future Trends in ERP for Manufacturing Sector

As technology continues to advance at a rapid pace, the future of ERP in the manufacturing sector is set to undergo significant changes. Here are some key trends that are predicted to shape the future of ERP for manufacturing:

1. Integration of IoT: The Internet of Things (IoT) is becoming increasingly important in manufacturing processes. ERP systems will need to seamlessly integrate with IoT devices to provide real-time data and insights. This will enable manufacturers to optimize their operations, improve efficiency, and make data-driven decisions.

2. Artificial Intelligence and Machine Learning: AI and machine learning technologies are poised to revolutionize ERP systems in the manufacturing sector. These technologies can help predict maintenance needs, optimize production schedules, and enhance quality control. By leveraging AI and machine learning, manufacturers can improve their processes and stay ahead of the competition.

3. Cloud-Based ERP Solutions: Cloud-based ERP solutions are gaining popularity in the manufacturing sector due to their flexibility, scalability, and cost-effectiveness. Manufacturers are increasingly adopting cloud-based ERP systems to streamline their operations, facilitate collaboration, and access real-time data from anywhere, at any time.

4. Mobility and Accessibility: With the growing trend of remote work and on-the-go operations, mobility and accessibility are becoming key considerations for ERP systems in the manufacturing sector. Manufacturers are looking for ERP solutions that are accessible on mobile devices, allowing employees to access critical data and perform tasks from anywhere.

5. Sustainable Manufacturing Practices: One of the emerging trends in the manufacturing sector is the focus on sustainability. ERP systems will need to incorporate features that help manufacturers track and reduce their environmental impact. This may include functionalities for monitoring energy usage, waste management, and supply chain sustainability. By embracing sustainable manufacturing practices, manufacturers can not only meet regulatory requirements but also appeal to environmentally-conscious consumers.

Overall, the future of ERP in the manufacturing sector is promising, with advancements in technology shaping the way manufacturers operate. By staying ahead of these trends and adopting innovative ERP solutions, manufacturers can improve their efficiency, productivity, and competitiveness in an increasingly globalized market.